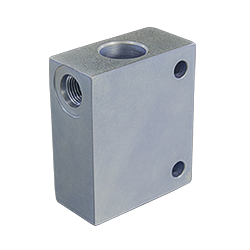

Material options

-

Wrought aluminum: In US, alloy 6061, temper designation T651 (The Aluminum Association) (ASTM B221 for Extruded Bar); In EU, 6082T651. Maximum pressure rating of 3,000 psi (210 bar), a proof rating of 6,000 psi (420 bar), and a burst rating of 12,000 psi (840 bar).

-

Ductile (nodular cast) Iron, In US, Grade 65-45-12 (ASTM A 536); in EU, EN16482:2014/ENGJS-400-15. Maximum pressure rating of 5000 psi (350 bar), a proof rating of 10,000 psi (700 bar), and a burst rating of 20,000 psi (1400 bar).

Aluminum surface treatments: Standard options

|

Clear Anodize - Class I, Type II Anodizing per Mil-A-8625F |

|

Black Anodize - Class II, Type II Anodizing per Mil-A-8625F |

Ductile iron surface treatments: Standard options

|

Chemical Blackening (SUN S-247-001) – Black oxide coating offers limited corrosion protection during shipping and storage. Amount of corrosion protection is minimal and varies depending on the environment it is stored in. Chemical blackening is standard on three-letter bodies. |

|

Trivalent Clear Zinc with Top Sealer (SUN S-247-017) – Trivalent Clear Zinc with Top Sealer is rated for 96 hours of protection per salt fog test per ASTM B117 or ISO 9227 5% saline. Trivalent Clear Zinc with Top Sealer is RoHs compliant. |

Ductile iron surface treatments: Custom options

|

Dewatering Oil (SUN S-247-000) – Dewatering oil offers limited corrosion protection during shipping and storage. Amount of corrosion protection is minimal and varies depending on the environment it is stored in. This is the standard option for custom integrated packages. |

|

Clear Zinc Nickel with Top Sealer (SUN S-247-018) – SAE AMS 2417, composition contains 10% to 20% Ni, with clear trivalent chromate treatment is rated for 1000 hours of protection per salt fog test per ASTM B117 or ISO 9227 5% saline. Clear Zinc Nickel is RoHs compliant. |

Download a PDF of this article.

For additional details on other Sun products' materials, see our "Cartridges: Materials of Construction" and "Seals: Materials of Construction."